the Contenders: Excavator Models for Small Projects

When considering excavators for small projects, the focus shifts overwhelmingly to two primary categories: Mini Excavators and Compact Excavators. While often used interchangeably, there are subtle but important distinctions based on operating weight, digging depth, and overall capability.

1. Mini Excavators (Micro to Small Mini)

Operating Weight: Typically ranging from 0.5 to 6 metric tons (approx. 1,100 to 13,000 lbs).

Key Characteristics:

Ultra-Compact Size: Designed for extremely tight access, often able to fit through standard garden gates or doorways.

Zero or Minimal Tail Swing: Many models feature zero tail swing (ZTS) or reduced tail swing (RTS) designs, meaning the counterweight stays within the width of the tracks when rotating. This is critical for working next to walls, fences, or other obstructions without risking damage.

Rubber Tracks: Almost exclusively equipped with rubber tracks to minimize damage to paved surfaces, lawns, and delicate landscapes.

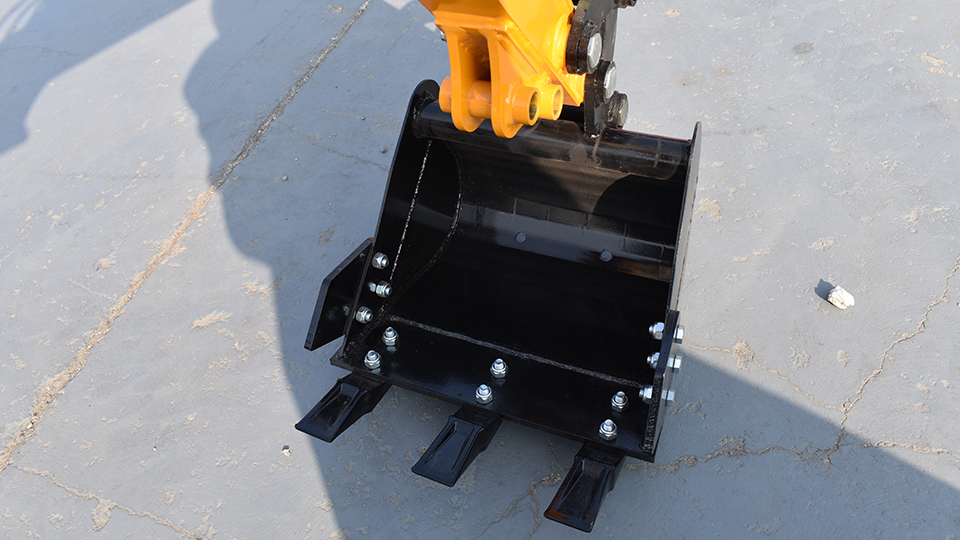

Auxiliary Hydraulics: Standard feature allowing for a range of hydraulic attachments.

Simplicity: Generally simpler controls and operation than larger machines, though still requiring proper training.

Sub-Categories within Mini Excavators:

Micro Excavators (0.5 - 1.5 metric tons):

Examples: Kubota K008-3, Bobcat E10, Cat 300.9D.

Best For: Extremely tight access areas, indoor demolition (electric models available), shallow trenching, small landscaping jobs, working around existing infrastructure.

Advantages: Can fit through standard doorways (some models have retractable undercarriages), extremely light footprint, minimal ground disturbance, highly maneuverable.

Limitations: Very limited digging depth and reach, minimal lifting capacity, slow travel speed, less powerful for breaking tough ground.

Ideal Project: Digging small trenches for irrigation in a residential backyard, minor indoor renovation demolition, delicate tree planting.

Small Mini Excavators (1.5 - 3 metric tons):

Examples: Kubota KX018-4, Bobcat E20, Cat 301.5.

Best For: Residential landscaping (pools, ponds, larger garden beds), utility trenching (water, gas, electrical), small foundation work, land clearing with small stumps.

Advantages: Good balance of power and compactness, still highly maneuverable, significantly increased digging depth and reach over micro excavators, better lifting capacity.

Limitations: Still limited for heavy rock breaking or very deep excavations, may struggle with very large stumps or dense clay.

Ideal Project: Installing a residential swimming pool, excavating for a home addition foundation, extensive garden landscaping.

2. Compact Excavators (Small to Mid-Size)

Operating Weight: Typically ranging from 6 to 10 metric tons (approx. 13,000 to 22,000 lbs). While the upper end of this range might verge on "medium-sized," models within this weight class often retain many characteristics suited for larger small projects.

Key Characteristics:

Increased Power & Digging Depth: Substantially more hydraulic power, digging force, and deeper digging capabilities than mini excavators.

Versatility: Capable of handling a wider range of tasks, including more significant earthmoving, light demolition, and handling larger attachments.

Operator Comfort: Often feature more spacious cabs, advanced controls, and amenities for extended operating hours.

Steel or Rubber Tracks: Can come with either rubber tracks (for versatility and reduced ground damage) or steel tracks (for maximum traction and durability in tough conditions).

Enhanced Stability: Larger footprint and heavier weight provide greater stability for lifting heavier objects or working on slopes.

Sub-Categories within Compact Excavators:

Small Compact Excavators (3 - 6 metric tons):

Examples: Kubota KX040-4, Bobcat E42, Cat 304.

Best For: Larger residential projects, light commercial site prep, significant utility work (sewer mains), land clearing with larger trees, small-scale demolition.

Advantages: A true "all-rounder" for many small to mid-size projects. Excellent power-to-weight ratio, good digging depth, can handle a wider range of attachments effectively (e.g., hydraulic breakers, larger augers).

Limitations: May still be too large for extremely confined residential backyards or interior work.

Ideal Project: Installing a new commercial septic system, preparing a site for a duplex, extensive brush clearing on acreage.

Mid-Size Compact Excavators (6 - 10 metric tons):

Examples: Kubota KX080-4, Bobcat E85, Cat 308.

Best For: Light civil engineering, significant commercial landscaping, larger trenching jobs, municipal utility work, and more substantial demolition projects.

Advantages: Approaching the power and capability of a full-size excavator for many tasks, but still more maneuverable and transportable. High lifting capacity, deep digging, efficient for moving large volumes of material.

Limitations: Less agile in very tight spaces, requires larger transport equipment, higher operating costs than smaller models.

Ideal Project: Major stormwater drainage installation, preparing a building pad for a small industrial unit, clearing and grubbing a multi-acre site.

Key Features and Technologies to Consider for Small Projects

Beyond the general size categories, several specific features and technologies can significantly enhance the suitability of an excavator for small projects:

Zero Tail Swing (ZTS) / Reduced Tail Swing (RTS):

Importance: Paramount for working in confined areas, next to buildings, walls, or fences. A ZTS excavator's counterweight does not extend beyond the width of its tracks when the superstructure rotates, greatly reducing the risk of collisions and enabling efficient work in tight spots. RTS models offer a slightly larger swing radius but are still far more compact than conventional excavators.

Retractable Undercarriage:

Importance: Found on micro and small mini excavators, this feature allows the track width to be hydraulically narrowed (e.g., from 39 inches to 28 inches). This enables the excavator to pass through standard doorways, narrow gates, or other constricted openings, then expand for greater stability during operation.

Two-Speed Travel:

Importance: Most compact excavators offer two travel speeds. A slower speed for precise maneuvering and heavy digging, and a faster speed for moving across the job site, which is crucial for efficiency on larger small projects.

Auxiliary Hydraulics (Standard & Proportional):

Importance: Essential for operating hydraulic attachments beyond the standard bucket. Standard auxiliary hydraulics provide basic flow, while proportional hydraulics allow the operator to precisely control the speed and power of the attachment (e.g., for delicate work with a hydraulic hammer or thumb). Look for multiple auxiliary lines for complex attachments.

Angling Blade/Backfill Blade:

Importance: The dozer blade at the front of the excavator is invaluable for backfilling trenches, grading, pushing material, and providing stability during digging. An angling blade (also known as a four-way or six-way blade) can be angled left or right, significantly increasing efficiency for grading, spreading, and backfilling without constantly repositioning the machine.

Hydraulic Thumb:

Importance: A game-changer for material handling. A hydraulic thumb attaches to the bucket and allows the operator to grasp and manipulate objects (rocks, logs, debris, concrete pieces) like a hand. This greatly enhances versatility, reducing the need for manual labor or additional equipment.

Boom Configurations (Swing Boom, Offset Boom):

Importance: Many compact excavators feature a swing boom (or offset boom) that allows the boom to swing independently of the house rotation. This enables the operator to dig trenches parallel to a wall, fence, or other obstruction, or to dig around corners without moving the entire machine. This is a critical feature for working in tight urban environments or residential settings.

Cab vs. Canopy:

Importance: For operator comfort and safety. A canopy provides overhead protection but no enclosure. A fully enclosed cab offers protection from elements, noise reduction, and often features heating/air conditioning. For extended workdays or adverse weather, a cab is a significant advantage.

Digging Depth and Reach:

Importance: Directly relates to the scope of work. Ensure the chosen model's maximum digging depth and horizontal reach are sufficient for the deepest trenches or farthest excavations required.

Lifting Capacity:

Importance: If the project involves lifting and placing heavy objects (e.g., pipes, concrete blocks, landscaping boulders), check the excavator's lifting capacity charts at various boom extensions.

Considerations Beyond the Machine Itself

Selecting the "best" excavator is not just about the technical specifications of the machine; it also involves practical considerations related to operation, logistics, and budget.

Transportability:

Crucial Factor: How will the excavator get to and from the job site?

Micro and small mini excavators can often be transported on a heavy-duty utility trailer towed by a capable pickup truck (ensure trailer and truck capacity meet the excavator's weight).

Larger compact excavators (3+ tons) may require a dedicated equipment trailer and a larger truck, or even professional transport services.

Consider the accessibility of job sites and whether a large truck and trailer can easily maneuver.

Rental vs. Purchase:

Usage Frequency: For occasional small projects (a few times a year), renting is almost always more cost-effective. It eliminates maintenance, storage, insurance, and depreciation costs.

Consistent Work: For contractors with consistent, frequent small projects, purchasing can be justified in the long run.

Try Before You Buy: Renting different models is an excellent way to test their suitability for your typical projects before committing to a purchase.

Operator Skill and Training:

Safety First: Regardless of size, excavators are powerful machines that require proper training and certification to operate safely and efficiently. Never operate without adequate training.

Learning Curve: Smaller excavators generally have a less steep learning curve than full-size machines, but precision operation still comes with practice.

Attachment Availability and Cost:

Versatility Enhancer: The true versatility of a compact excavator comes from its attachments.

Consider what attachments are readily available for rent or purchase (buckets of various sizes, hydraulic hammer, auger, grapple, hydraulic thumb, ripper, compactor plate).

Factor in the cost of attachments, as they can significantly add to the overall project expense.

Dealer Support and Service:

Reliability: Especially for purchased machines, reliable dealer support, parts availability, and service technicians are crucial to minimize downtime.

Rental Fleet Quality: For rentals, ensure the rental company maintains its equipment well and offers support if issues arise on site.

Popular Brands and Models for Small Projects

While specific model availability varies by region and rental fleets, some brands consistently offer excellent options for small projects:

Kubota: A market leader in mini and compact excavators, known for reliability, smooth hydraulics, and a wide range of models.

Popular Small Project Models: K008-3 (micro), KX018-4 (mini), KX040-4 (small compact).

Bobcat: Renowned for compact equipment, Bobcat excavators are popular for their robust build and performance.

Popular Small Project Models: E10 (micro), E20 (mini), E42 (small compact).

Caterpillar (Cat): Offers a comprehensive range of mini and compact excavators with advanced features and global support.

Popular Small Project Models: 300.9D (micro), 301.5 (mini), 304 (small compact).

John Deere: Strong presence in North America with durable and user-friendly compact excavators.

Popular Small Project Models: 17G (mini), 30G (small compact).

Volvo: Known for premium quality, operator comfort, and efficient performance in their compact excavator line.

Popular Small Project Models: EC15E (mini), EC20E (mini), ECR25D (compact).

Yanmar: Pioneers in mini excavators, known for compact designs, fuel efficiency, and smooth operation.

Popular Small Project Models: ViO17 (mini, zero tail swing), ViO35 (compact, zero tail swing).

Takeuchi: Highly regarded for their robust build quality, powerful hydraulics, and excellent operator comfort.

Popular Small Project Models: TB210R (mini, retractable undercarriage), TB235-2 (compact).

This list is not exhaustive, and many other reputable manufacturers offer excellent compact excavator options.

Case Studies: Matching the Machine to the Project

To illustrate the selection process, consider these hypothetical small projects:

Case Study 1: Residential Backyard Trenching for Irrigation

Project Needs: Digging shallow (1-2 ft deep) trenches for an irrigation system across a lawn, navigating around existing landscaping, and fitting through a standard 36-inch gate. Minimal soil removal.

Ideal Excavator Model: Micro Excavator (e.g., Kubota K008-3, Bobcat E10).

Why: Its extremely narrow width (especially with a retractable undercarriage) allows it to easily access the backyard without damaging the gate or fence. Its light weight minimizes turf disturbance. The small digging depth and reach are perfectly adequate for irrigation lines. Minimal power is needed for soft ground.

Case Study 2: Foundation for a Two-Car Garage

Project Needs: Excavating footings approximately 3-4 feet deep and 2 feet wide for a 20x20 ft garage. Soil is mixed clay and loam. Need to pile excavated soil nearby.

Ideal Excavator Model: Small Mini Excavator (e.g., Kubota KX018-4, Cat 301.5).

Why: Offers sufficient digging depth and breakout force for typical garage footings. Still compact enough for maneuverability on a residential lot. The front blade is useful for leveling the base and pushing soil. Good balance of power and precise control for forming square trenches.

Case Study 3: Commercial Site Prep for a Small Retail Outbuilding

Project Needs: Clearing a 1/4-acre lot of brush and small trees (up to 6-inch diameter), excavating for a small building pad, installing new sewer and water lines (up to 8 ft deep), and light grading. Requires moving small boulders.

Ideal Excavator Model: Small Compact Excavator (e.g., Kubota KX040-4, Bobcat E42) with a hydraulic thumb and possibly a breaker attachment.

Why: The increased power and digging depth are essential for deeper utility trenches and handling larger brush/small trees. A hydraulic thumb is invaluable for picking up and moving cleared debris and boulders. Its weight and stability allow for more efficient light grading and use of a hydraulic breaker for any concrete or rock. Still relatively transportable.

Conclusion: Precision, Power, and Portability for Small-Scale Success

Choosing the "best" excavator for small projects is ultimately about striking the right balance between capability and constraint. There isn't a one-size-fits-all answer, but rather an optimal match between the machine's features and the demands of the job.

For extremely confined spaces and delicate work, the micro excavator is unparalleled in its ability to access and operate where no other machine can. As project size and depth requirements increase, the small mini excavator offers a versatile sweet spot, balancing compactness with significantly enhanced digging and lifting capabilities. For more demanding "small" projects that approach light commercial or extensive residential work, the small compact excavator provides a formidable combination of power, reach, and attachment versatility, acting as a mini powerhouse.

Key considerations like zero tail swing, retractable undercarriages, proportional auxiliary hydraulics, and angling blades are not merely optional extras but often defining features that enable successful and efficient operation in tight environments. Furthermore, understanding transport logistics, considering rental versus purchase, prioritizing operator training, and ensuring access to a range of suitable attachments are all crucial components of a well-informed decision.

By meticulously evaluating project scope, site conditions, desired capabilities, and budget, contractors and homeowners alike can confidently select the excavator model that will transform their small projects from challenging tasks into efficient, successful endeavors. The compact excavator segment continues to innovate, offering increasingly sophisticated and powerful machines that empower operators to achieve impressive results, even in the smallest of spaces.

Post time:Sep-25-2020