The Lifespan of a Workhorse: A Technical Analysis of Excavator Durability

The question of an excavator's lifespan is far more complex than a simple number of years. For a machine that can weigh over 100,000 pounds and operates under immense stress, its life is not measured by the calendar but by its service hours and the cumulative effect of its operational history. While a new excavator from a reputable manufacturer is engineered for a long and productive life, its actual longevity is a direct result of several critical factors, from maintenance protocols to the severity of its application. This technical article will explore the industry benchmarks for excavator lifespan, dissect the key variables that influence it, and provide a framework for maximizing the return on this significant capital investment.

1. The Primary Metric: Why Service Hours Matter

In the heavy equipment industry, the most accurate measure of a machine's lifespan is its total number of service hours, not its age in years. An excavator that is ten years old with only 5,000 hours on its meter has had a very different life than a five-year-old machine with 15,000 hours. The service hour meter records every hour the engine is running, representing the actual work performed and the wear and tear on all major components.

Industry Benchmark: For a well-maintained, mid-sized

from a reputable brand (such as Caterpillar, Komatsu, or Volvo), the general industry benchmark for its "first life" is typically between 10,000 to 15,000 service hours. At this point, the machine may require a major overhaul of the engine, hydraulic pumps, or other critical systems to continue operating reliably. It is not uncommon for a machine to reach 20,000 hours or more with a properly executed overhaul program.

2. The Critical Factors Governing an Excavator's Lifespan

The disparity in a machine's potential lifespan can often be traced back to four primary technical and operational factors.

Maintenance and Service History (The Single Most Important Factor):

The most significant predictor of an excavator's longevity is its maintenance schedule. Adherence to a strict preventive maintenance program is non-negotiable. This includes:

Fluid and Filter Changes: Regular changes of engine oil, hydraulic fluid, and fuel and air filters are vital. Contaminated fluids can lead to catastrophic component failure. Engine oil analysis, a technical service offered by many dealers, can detect microscopic metal particles, signaling impending failure in the engine or hydraulic system long before a visible issue arises.

Greasing and Lubrication: The boom, stick, bucket linkage, and slew bearings require daily lubrication to prevent premature wear. Failure to do so can lead to costly pin and bushing replacements or, in severe cases, structural damage.

Genuine Parts: Using genuine, manufacturer-approved parts and fluids ensures that components are engineered to the machine's exact specifications, maintaining system integrity and performance.

Application and Operating Conditions:

The type of work an excavator performs directly influences its rate of wear.

Heavy vs. Light Duty: An excavator used for rock excavation, demolition, or quarry work will experience significantly higher stress on its boom, stick, hydraulic cylinders, and undercarriage compared to a machine used for digging trenches in soft soil.

Environmental Factors: Operating in extremely dusty environments accelerates the wear of air filters and engine components. Working in saltwater or corrosive environments can lead to premature rust and component degradation.

Operator Skill and Practices:

A skilled operator can add thousands of hours to a machine's life, while a careless one can drastically shorten it.

Proper Warm-up: Allowing the engine and hydraulic system to warm up to operating temperature before putting them under load is crucial to prevent premature wear on seals and pumps.

Smooth Operation: Aggressive, high-impact digging and swinging, or using the machine's own force to break rock, puts enormous strain on the boom, stick, and undercarriage. A smooth, controlled operator minimizes these destructive forces.

Minimizing Idling: Excessive idling wastes fuel and contributes to engine wear without a return on investment. Modern machines are equipped with auto-idle shutdown features, but operator awareness remains key.

Quality of Manufacturing (The "Reliable Excavators" Factor):

The inherent design and build quality of a machine set its baseline potential for longevity. Top-tier manufacturers invest heavily in metallurgy, component engineering, and advanced manufacturing processes.

Robust Structural Components: The boom, stick, and frame are designed to withstand massive forces. Brands known for reliability use high-strength steel and advanced welding techniques to prevent cracking.

Durable Undercarriage: The undercarriage is a critical wear item, but a well-designed one with durable tracks, rollers, and sprockets will last much longer.

Advanced Engine and Hydraulic Components: High-quality engines and hydraulic pumps are engineered to run for thousands of hours with minimal degradation, provided they are properly maintained.

3. Component-Specific Lifespan Benchmarks

Rather than thinking of the machine as a single unit, it's more technically accurate to consider the lifespan of its major systems.

Engine: The engine is often the first major system to require a significant overhaul. With a strict maintenance schedule, a modern diesel engine can be expected to run for 10,000 to 15,000 hours before needing a rebuild.

Hydraulic System: Hydraulic pumps and motors are complex and can be expensive to replace. The main hydraulic pump typically lasts for over 10,000 hours before a rebuild is necessary. Cylinders and hoses, while having a shorter life, are generally considered replaceable wear items.

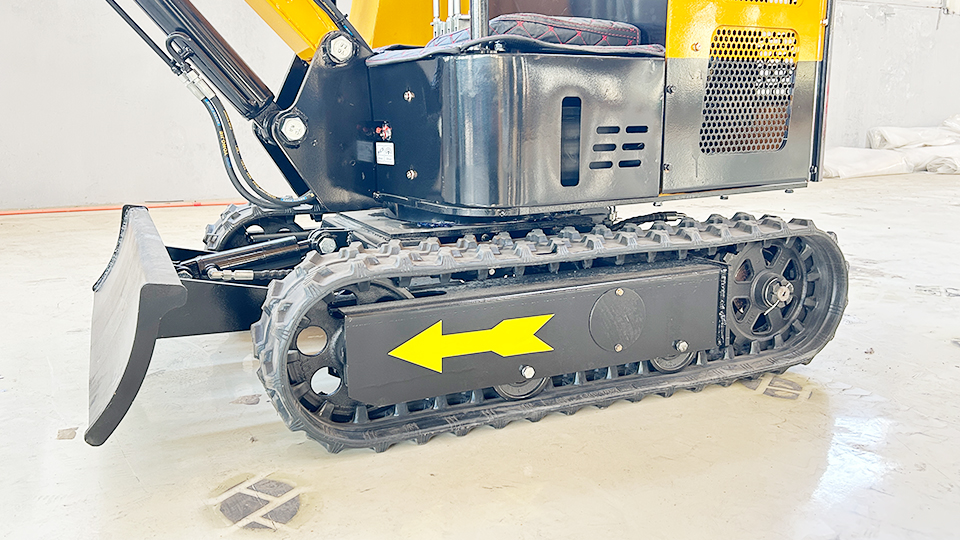

Undercarriage: The undercarriage is a constant wear item. Its lifespan is highly dependent on the application and operating surface. Tracks, rollers, and sprockets may need replacement between 3,000 and 7,000 hours, with a full undercarriage rebuild often required around 7,000-10,000 hours of operation.

Structural Components (Boom and Stick): The structural life of these components is largely tied to the machine’s application. For machines used in standard digging, the boom and stick can last the life of the machine. However, for demolition or rock-breaking applications, fatigue and cracking can occur much sooner.

4. Leveraging Technology to Extend Lifespan

Modern excavators are equipped with technology that can significantly extend their service life.

Telematics Systems: Systems like KOMTRAX (Komatsu) and Cat Connect (Caterpillar) provide fleet managers with real-time data on machine health, service hours, and diagnostic codes. This enables proactive maintenance scheduling and helps to identify potential issues before they become critical failures.

Onboard Diagnostics: Advanced electronics and sensors in today's machines continuously monitor engine and hydraulic system performance, alerting operators to issues before major damage occurs.

Conclusion

An excavator's lifespan is not a fixed number but a variable influenced by a confluence of technical and operational factors. While a reliable, well-engineered machine provides a solid foundation, its true longevity is ultimately determined by a commitment to rigorous maintenance, professional operation, and an understanding of its limitations. By viewing an excavator not just as a piece of iron but as a sophisticated mechanical system that requires ongoing care, operators and fleet managers can expect to see their machines reliably perform for well over a decade, often surpassing 20,000 hours with major overhauls, and delivering a strong return on their investment.

Post time:Sep-25-2020